Perfection is just one turn away

Perfection is just one turn away

Language:

| Order number | 72.785.005 |

|---|---|

| Product description | Screw cap micro tube, working volume: 0.5 ml, skirted conical base, transparent, cap: natural, cap assembled, sterile, 100 piece(s)/bag |

| Graduation | no |

|---|---|

| Cap | standard screw cap |

| Closure type | screw cap |

| Knurls | no |

| Base shape | skirted conical base |

| Volume of work | 0,5 ml |

| Centrifugation max (RCF) | 20000 x g |

| Diameter | 10.8 mm |

|---|---|

| Length of product | 44 mm |

| Product material | Polypropylene (PP) |

|---|---|

| Colour of product | transparent |

| Closure material | Polypropylene (PP) |

| Colour of cap | natural |

| O-ring material | Ethylene propylene diene rubber (EPDM) |

| Satisfies the requirement | IATA |

|---|---|

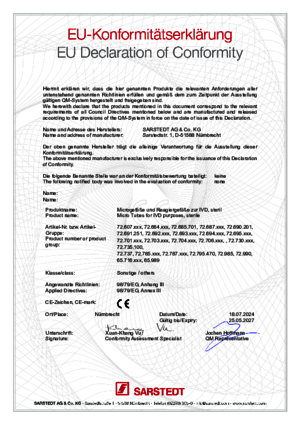

| Product category | In vitrodiagnostic device, CE |

| CE certified | CE |

| Purity standard | sterile |

| Sterilisation | Electron irradiation |

| Batched | yes |

| Minimum order qty. | 1000 |

|---|---|

| Type of smallest subpackaging | bag |

| Piece(s) / inner box | 100 |

| Piece (s) / outer case | 1000 |

| Piece(s) / pallet | 96000 |

| Depth of case | 348 mm |

| Width of case | 278 mm |

| Height of case | 140 mm |

| Case volume | 0.0135 cbm |

| Weight of product | 0.0015 kg |

| Weight of case | 1.81 kg |

| EAN of inner box | 4038917120692 |

| EAN case | 4038917077682 |

The total length including the cap is 46.0 mm, with the cap attached it is 49.0 mm. The diameter underneath the mounting bundle is 10.8 mm. This means they can be used in most common microcentrifuges without any problems.

Our screw cap micro tubes have been used at temperatures below zero centigrade for decades. Based on our general experience, the screw cap micro tubes can be used to freeze aqueous solutions at temperatures of up to -86°C, except in the case of demineralised water (purified water) solutions. With demineralised water, there are generally critical freezing situations which can lead to the formation of cracks. Here, successful freezing of the tubes is always dependent on many factors. These include the medium to be frozen, the rack used and the mechanical load on the tubes. The use of tubes at temperatures below zero centigrade should therefore be tested under the routine conditions of the user.

For cryopreservation, we recommend using Sarstedt's CryoPure tubes.

The torque for caps for machine tightening should be between 15 and 18 Ncm.

All micro tubes type A, C, E, G and I can be provided with a 25 x 21.5 mm label in the factory. Depending on the requirements, the label can be printed individually and with different colours. Labels with all common barcode types can also be printed.

Since the labels are exposed to different stresses depending on the application – temperature fluctuations, contact with liquids and/or chemicals – labels and printing inks made of various different materials are available. The minimum purchase volume is determined individually.

The shipping of samples on dry ice is a common method, but we are aware of some problems associated with this type of shipping. When shipping in this manner, it is necessary to ensure that the tubes are packed so that they are protected as well as possible and appropriately fastened to avoid damage.

Our micro tubes can be centrifuged up to 20,000 x g. Tested with density solution (density: 1.06 g/ml) filled up to a nominal volume, at 20°C for 15 minutes in the fixed-angle rotor.

Our SafeSeal reaction tubes can be centrifuged up to 30,000 x g (2.0 ml up to 25,000 x g). Tested with demineralised water (density: 1.06 g/ml) filled up to a nominal volume, at 20°C for 90 minutes in the fixed-angle rotor.

Standard reaction tubes can be centrifuged at up to 20,000 x g. Tested with demineralised water (density: 1.06 g/ml) filled to nominal volume, at 20°C for 15 min. in a swing-out rotor. Our SafeSeal reaction tubes can be centrifuged at up to 30,000 x g (2.0 ml at up to 25,000 x g).

Screw cap micro tubes and reaction tubes can be autoclaved at 121°C without any appreciable loss of mechanical properties. When doing this it is important not to screw on/push down the cap to seal it. The user must check whether other product characteristics are affected by autoclaving in terms of the desired use.